Ball and Race mill pulveriser YouTube

Mar 05, 2017· How Ball Mills Work (Engineering and Mining) Duration: 15:30. saVRee 3D 17,431 views. ... Pulverizer Mill of pulverized coal boiler in thermal power plant Duration: 3:46.

WhatsApp)

WhatsApp)

Mar 05, 2017· How Ball Mills Work (Engineering and Mining) Duration: 15:30. saVRee 3D 17,431 views. ... Pulverizer Mill of pulverized coal boiler in thermal power plant Duration: 3:46.

Nov 17, 2012· pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal and air mixture is then transport to the boiler burner ...

For nearly 100 years—ever since pulverized coal combustion was adapted for power generation—GE has been a leader in coal mill technology for the power industry. That leadership continues today with the world''s largest fleet of installed power milling equipment.

Without performance driven maintenance pulverizer performance could look like this.. This was a ball tube mill and the issues started with reject lines were not working properly, classifier blades out of synchronization, +3" on crusher dryer clearances. In Conclusion •Overhauls do not guarantee good performance •Performance must be

Collecting coal samples using an isokinetic probe provides the best data describing actual operating conditions inside the coal pipe. Source: Storm Technologies Inc. The isokinetic coal sampling method, although more difficult, is the best option for determining the true mill coal fineness produced and to calculate pulverizer performance.

Home → Products → Coal Power → Ball Mill Pulverizer Wear Parts Get superior wear part performance for EL type coal pulverizers. Columbia Steel has earned a reputation for top service and quality replacement parts for EL coal pulverizers.

pulverized coal ball mill. This mill uses central horizontal shaft which has a number of arms, and a beater of different design is attached to these arms to beat the coal to be pulverized. High speed impact mills are mainly used in pulverizing lignite. Today all boiler designers opt to use ball or vertical spindle mill for coal other than lignite.

A wide range of modifications and upgrades are available for your BW Roll Wheel™ rollertype or E/EL ballandrace pulverizers. ... Pulverizer / Mill Upgrades. Roll Wheel Pulverizer Upgrades ... abrasionresistant material with BW''s expertise in coal pulverizer and boiler design, operation and optimization. ...

Pulverized In Tube Mill And Ball Mill. ihi coal pulverizer mill ball mill smoothfab. Pulverizer Wikipedia, the free encyclopedia High Speed; Low Speed Ball and tube mills A ball mill is a pulverizer that consists of a horizontal rotating, .

offers 1,287 pulverizer ball mill products. About 37% of these are mine mill, 2% are ceramics, and 1% are other fabrication services. A wide variety of pulverizer ball mill options are available to you, such as ac motor, dc motor, and stepper motor.

Coal Mill Great Wall Corporation,The coal is grinded into pulverized coal in the coal ball mill mainly by means of three ways press strike and grind Among them the first way is the most energysaving and the last one most energyconsuming During the milling process all kinds of coal mills use two or .

Pulverized coal ball millLangzhong mill pulverized coal burstgeyser pulverized coal ball mill ball material a pulverizer or grinder is a mechanical device for the pulverized wet ball mill ball materialPulverized coal ball mill ball material the ball and tube mills are lowspeed machines that grind the coal with steel balls in. Oline Chat

From our original E/EL ballandrace type pulverizers for lower capacity applications, to the latest BW Roll Wheel™ pulverizer capable of grinding up to 230,000 pounds of coal per hour (104,300 kg/hr), we set the standard for high availability, reliability and low maintenance.

coal mill is one of the four auxiliary machines in thermal power station and the main equipment of pulverized coal preparation system is also suitable for pulverizing coal and ore in cement, metallurgy, chemical industry and other industriesecial steel ball coal mill is a new type of equipment widely used in thermal power plants.

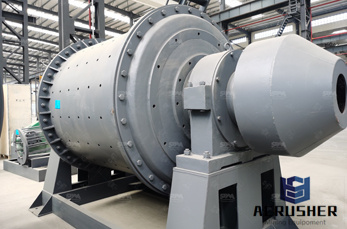

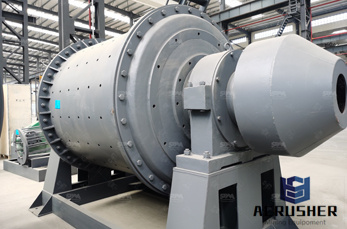

Low Speed Ball and tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder. Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill.

Dec 13, 2011· This mill uses central horizontal shaft which has a number of arms, and a beater of different design is attached to these arms to beat the coal to be pulverized. High speed impact mills are mainly used in pulverizing lignite. Today all boiler designers opt to use ball or vertical spindle mill for coal other than lignite.

Thermal power plants use different types of coal pulverizers. The method used is attrition, impact, or a combination of both. This article explains the characteristics of the three main types attrition, impact and attrition, and impact or hammer. Selection of the type of pulverizer depends on the grindability of the coal, the capital costs and maintenance costs, and considerations for licensing.

11 rows· Coal ball mill is a machine that crushes and grinds the coal briquette into pulverized coal. .

The mediumspeed coal mill is one of the series of pulverizing equipment produced by Heavy Industry Technology. It is widely used in the pulverized coal pulverizing system of bituminous coal. It is mainly used for grinding of medium

with A high pulverizer inlet temperature provides high conductive heat transfer suffi cient for spontaneous combustion. When pulverized coal is allowed to remain in a high temperature environment, fire potential exists. Figure 4 compares a conventional vertical table type pulverizer with a ball tube mill pulverizing system with crusher ...

Nov 23, 2013· BALL TUBE MILL Tube mills are employed to pulverize the precrushed raw coal to the required fineness before it is admitted into the boiler furnace for combustion. The operating characteristics Faster response to Load variation of tube mills make it the best mill available for the direct firing system of the coal.

Ball mill also are considered to be one of the highly useful and required equipments for industrial utilities. We are efficiently engaged in the line of manufacture, supply and export of one of the most efficient and productive kinds of ball mills also.

Pulverized Coal Ball Mill Ball Material. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

Oct 12, 2017· Today we will learn about difference between sag mill vs ball mill. A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding, crushing or cutting. This commutation is an essential part of many processes. Various kinds of mills are there with which different material processing takes place.

WhatsApp)

WhatsApp)