(PDF) Underground mining Methods ResearchGate

Underground Mining Methods; Soft rock Mining Methods; Blast mining; Shortwall mining;Coal Skimming (or Sink and Float) method; Hard rock Mining Methods.

WhatsApp)

WhatsApp)

Underground Mining Methods; Soft rock Mining Methods; Blast mining; Shortwall mining;Coal Skimming (or Sink and Float) method; Hard rock Mining Methods.

Apr 27, 2016· Today there are a wide variety of powered hand tools that can be used for hand drilling. However, this still limits hand test drilling for small scale gold mining. The benefit of hard drilling is the reduced cost compared to larger methods, and this may be the best method for individual prospectors who lack the resources for larger exploration.

Before hard rock mining operations have even begun, companies explore areas where gold may be found and scientifically analyse the rock. The actual gold originates deep within the earth in places called pockets. These pockets are filled with gold, heavy ore, and quartz. If enough gold is discovered in the ore, the technological process of hard ...

Hard rock mining is the process of using open pit or underground mining tunnels to retrieve the gold from the rock. This method of gold mining is responsible for recovering most of the worlds gold supply. Byproduct mining is related to hard rock mining in that open pit or underground mining .

Openpit mining, or opencast mining is a surface mining technique of extracting rock or minerals from the earth by their removal from an open pit or borrow.. This form of mining differs from extractive methods that require tunneling into the earth, such as long wall mining. Openpit mines are used when deposits of commercially useful minerals or rocks are found near the surface; that is ...

Gold Mining Equipment List. Making a complete list of gold mining equipment starts with defining the type of gold mining you are doing and the budget you have at your disposal. The type of mining relates to hard rock, eluvial, or placer; alluvial capital budget you have to invest in buying your equipment with dictate the scale at which you want to mine and influence the longterm ...

Man knew more about gold itself and lusted for it much before he understood the geology of hard rock gold or its deposits. Man had to learn about hard rock extraction methods and how to locate those gold deposits just to satisfy the thirst for that yellow metal. Gold has been the most highly esteemed and sought after precious commodity since the times of antiquity It has spurred on numerous ...

Placer mining, hard rock mining, byproduct mining and by processing gold ore. Placer mining Placer deposits are composed of relatively loose material that makes tunneling difficult, so most extraction methods involve water or dredging.

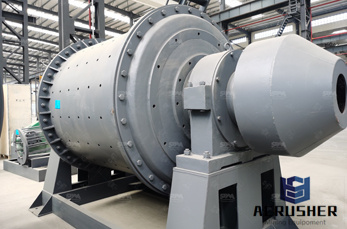

The gold recovery process for the Hardrock Project consists of a crushing circuit (gyratory and cone), a grinding circuit HPGR and ball mill, pre leach thickening, a leach and carboninpulp ("CIP") circuit, cyanide destruction and tailings disposal, carbon elution and electrowinning, carbon regeneration and a gold .

Hardrock mines followed quartz veins, which contained gold. Underground mining was very expensive as tunnels had to be blasted and the roofs supported. Mines such as those at Waihī on Coromandel Peninsula and Waiuta on the West Coast followed reefs until they became too deep or low grade to be mined economically.

Gold deposits live in igneous or metamorphic rock, which is relatively hard, as do diamonds, copper, silver, nickel and zinc [source: Great Mining]. Even within the hardrock category, design and extraction methods vary, but almost all revolve around a few basic techniques:

In the paper, I make a detailed introduction to the hard rock gold mining from the rock gold geology, reserves, processing methods, to gold processing equipment. By reading this article, you are sure to have a generally clear and organized understanding of rock gold. Join us! Hard rock gold is also called mineral gold which is produced in mines ...

It was underground, hardrock mining operations that transformed California gold mining into a corporate activity. It was in the Northern Mines, clustered around Grass Valley, which dominated underground mining. In the beginning, the goldbearing quartz was wrenched from underground veins by backbreaking, dimly lit sweat and blood.

Dec 12, 2019· Hard rock mines include most metal and diamond mines. They tend to be deep, and the orebody is often steeply inclined (or dipping). Shafts can be as a deep as several kilometres. Access from the surface is via a shaft or a decline. There is a variety of mining methods used, often in the same mine, depending on the geometry of the orebody and ...

Fundamentally, underground hard rock mining has changed very little over the last century or so. Shafts and tunnels are excavated and constructed to allow miners to reach an ore zone, the ore body is broken up using blasting or other methods, and the resulting material transported along tunnels and up shafts to the surface where it is crushed and processed.

Bodie''s source of gold came from hard rock mining – mining that requires breaking apart ore to extract gold that''s intermingled with the rock. There are many steps to this kind of mining; here are some of the steps: Ore extraction. Basically, "ore extraction" means digging. Digging for A LOT of solid rock .

Hard Rock Prospecting Techniques. Chris Ralph from ICMJ''s Prospecting Mining Journal explains how to identify, locate, and extract gold from hard rock. Explore the Kentucky Mine to see how the old timer''s worked. Extended DVD takes you to the next level! See a miner who uses small scale equipment to process a larger volume of ore from his ...

Hard rock, or "Lode" gold is still contained within ore, and various methods are used to extract the metal from the rock that surrounds it. Placer gold on the other hand occurs when natural erosion has released the gold from its host material and the gold is now a separate piece, whether that be a small speck of gold dust or a large gold ...

we now serve hard rock mining WE ARE : Chemical Free Gold Recovery, Gold Density Recovery, Gold Concentrate, Black Sand Separator, Processing Gold In Bulk, Fine Gold Processing, Fast Gold Processing( 20 Ounces in 2 Hours ), Fine Gold Recovery Size ( 20 to Minus 2,000 Mesh ) Flour Gold Recovery – UP TO 15 YARDS PER DAY

Underground mining (hard rock) Underground hard rock mining refers to various underground mining techniques used to excavate hard minerals such as those containing metals like gold, copper, zinc, nickel and lead or gems such as diamonds. In contrast soft rock mining refers to excavation of softer minerals such as coal, or oil sands. Mine Access

Hard Rock Mining. Hard rock mining is the process of gathering rocks with gold veins and using large tools to remove the gold. This type of mining is most commonly used today.

In the paper, I make a detailed introduction to the hard rock gold mining from the rock gold geology, reserves, processing methods, to gold processing equipment. By reading this article, you are sure to have a generally clear and organized understanding of rock gold. Join us! Hard rock gold is also called mineral gold which is produced in mines ...

Summary. Historically, the majority of gold was mined from "placer deposits", where gold has settled out of an existing or ancient waterway downstream of where nuggets had eroded out of rock early miners also used an early form of hardrock mining, digging solid veins of gold out of rock, where mineralized water had deposited it over thousands of years.

After the rock was pulverized, the miners then used gold pans for final processing. As time went on, gold mining became increasingly more sophisticated. The solitary gold miner of the 1840s gave way to hundreds of miners toiling in deep hard rock mines, such as those found in Jackson and Grass Valley.

WhatsApp)

WhatsApp)