loesche Vertical Mill LM YouTube

Nov 16, 2011· Process in vertical raw mill. This feature is not available right now. Please try again later.

WhatsApp)

WhatsApp)

Nov 16, 2011· Process in vertical raw mill. This feature is not available right now. Please try again later.

ones replaced the gearboxes of a horizontal cement mill and a horizontal raw mill in 1993. Both new gearboxes were of CPU type. The latest installation was a WPU type gear unit for another vertical raw mill in 2005. Cementos La Cruz Azul also encountered problems with the gearbox of a Polysius roller mill type RM/46/26 for raw grind

Recently, especially from 1980s, grinding system using the vertical roller mill, which has effective grinding performance, is developed and applied in the cement grinding process. Descriptions . Basic equipment structure of the vertical roller mill for cement grinding is the same as the vertical roller mill of raw material and coal grindings.

Cement mill3 of 110 TPH at cm 2 /gram Blaine. The ground cement is stored in five silos for final dispatch. A dynamic separator was installed in place of the old separator in cement mill1 to improve the grinding capacity as well as the cement strength at lower fineness to meet the requirement of international standard for strength.

Aug 15, 2018· Kohat – Pakistani Kohat Cement Company Ltd. has recentlyordered as many as four vertical roller mills (VRM) from LOESCHE in order to expand their cement plant in .

Milling Trenches in concrete with Power Profilers is a very common application. Weather it is for Culvert installation (as the video to the left shows) or installing cabling in concrete pavements, trenching concrete for plumming or other purposes, Schibeci''s range of concrete milling machines for small and large skid steers can be part or all of your solution.

Sep 11, 2013· LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations. Special ...

The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill''s modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills .

Raw Material Vertical Roller Mill. Our raw materials vertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsum. These units can process both raw and recycled materials, while helping to reduce waste and preserve supplies of these materials.

Cement Additives Division 1 Improvement of cement performances through the use of grinding aids in vertical roller mill ''Arcangelo, – Mapei SpA, Milan, Italy Abstract Due to the stringent requirement of energy saving, the use of vertical roller mills for cement grinding is now common.

Cement vertical mill is mainly used for grinding cement recent years, with the vertical mill design, manufacturing technology, grinding process innovation, Vertical cement mill as cement grinding equipment, has been successfully applied in foreign annual production of cement vertical mill used in cement industry is 30 ...

And we also use coal mill type: The cement project is the largest cement factory building in the same time, used just one year . We use 18 loesche mills.loesche.

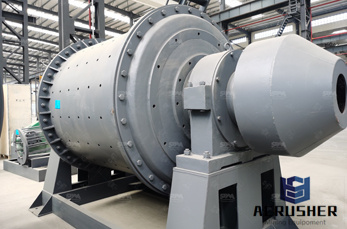

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum .

Participated in the commissioning of Loesche Vertical Raw mill (LM ) installed by SINOMA Nanjing/Handan at Bestway Cement Ltd, Farooqia plant. Participated in the commissioning of 02 Loesche Vertical Cement mills (LM +2) installed by SINOMA Nanjing/Handan at Bestway Cement Ltd, Farooqia plant. Activity

additions of approximately 5 percent gypsum to control the setting properties of the cement can be done in ball mills, ball mills in combination with roller presses, roller mills, or roller presses. While vertical roller mills are feasible, they have not found wide acceptance in the Coarse

vertical vertical roller mill in cement. vertical roller mills in cement plant ghana May 19, 2017 shfwh. Cement Industry Directory – International Cement. Loe a company or product in the cement industry using the search engine, alternatively pick a product/service from the main egories below to find companies . Get Price

LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology. Our designers are constantly coming up with new ideas and even more dependable components to reduce the already acclaimed low failure rate of our mills.

MVR vertical roller mill with MultiDrive ... The highest wear occurs on the wear parts of the grinding elements as is the case with any type of vertical mill. Therefore, ease of replacement and regeneration is a major feature of the mill. ... MVR 6300 C6 cement mill with MultiDrive®, Cherat Cement Co. Ltd., Cherat, Pakistan.

Aug 30, 2012· This saves the extra fuel cost and makes cement somehow economical. Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing. For example shale, fly ash, mill scale and bauxite.

Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity. In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 %.

Vertical cement mill CHAENG. One cement factory in China purchased cement vertical mill from CHAENG in 2012. This vertical mill is the first and the largest cement vertical mill in China, adopting new efficient powder separator, easy to operate and operating stably.

1. Ball Mill (BM): historically the mill of choice, it still predominates today and accounts for > 85% of all cement mills installed globally; 2. Vertical Roller Mill (VRM): commonly used for grinding of granulated slag but increasingly also for cement grinding and accounts for approximately 15% of the global cement mills.

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

One cement factory in China purchased cement vertical mill from CHAENG in 2012. This vertical mill is the first and the largest cement vertical mill in China, adopting new efficient powder separator, easy to operate and operating stably. Its designed output is 220t/h, and the actual output is .

WhatsApp)

WhatsApp)