(PDF) DESIGN AND FABRICATION OF MINI BALL MILL .

PDF | This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would ...

WhatsApp)

WhatsApp)

PDF | This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would ...

China Tencan 2019 Newest Design Ultrafine Vertical Planetary Ball Mill For Glove Box Use,Minilab Sample Grinder, Find Complete Details about China Tencan 2019 Newest Design Ultrafine Vertical Planetary Ball Mill For Glove Box Use,Minilab Sample Grinder,Planetary Ball Mill For Glove Box Use,Lab Sample Grinder,Mini Lab Grinder from Grinding Equipment Supplier or .

grinding limestone design vlastnistudnacz Limestone Grinding Mill Design VM series Vertical Grinding Mill is a kind of large scale powder mill which is designed specially to solve the problems of low limestone crusher and grinder limestone grinding process crusher grinder project plan for limestone crushing mill project limestone crusher belt ...

design for vertical ball mill design for vertical ball mill offers 60 ball mill products. About 45% of these are crusher, 23% are mine mill, and 18% are mining machinery parts. A wide variety of ball mill options are available to you, Ball Mill. design for vertical ball mill offers 60 ball mill products. SERVICE ONLINE ...

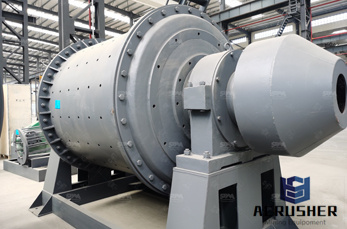

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

vertical raw mill design ppt ball mill used in cement ppt. Jobs 1 10 of 1000 ... raw mill cement plant ppt free download ... Get Price Vertical Raw Mill Cement Industry Ppt Some Information About vertical raw mill . ... of heavy equipment filetype ppt 19 Jun 2013 mining machine design filetype pdf . Contact Supplier

Jun 18, 2015· LM Series Vertical Grinding Mill ZENITH. Skip navigation Sign in. Search. ... The Ingenious Design of the Aluminum Beverage Can Duration: ... Ball Mill, Vertical Roller Mill) .

cement mill calculation pdf . Cement grinding Vertical roller mills versus ball mills. cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement .

Vertical raw mills are widely used in the concrete and mining fields, and are also used to process gypsum. These units can process both raw and recycled materials, while helping to reduce waste and preserve supplies of these materials. cement vertical raw mill design Cement Vertical Raw Mill Design croissyannelibe.

New Design Vertical Chocolate Ball Mill Machine, Find Complete Details about New Design Vertical Chocolate Ball Mill Machine,Chocolate Ball Mill Refiner Chocolate Ball Mill,Ball Mill For Chocolate,Chocolate Grinding Machine from Chocolate making machine Supplier or ManufacturerChengdu LST Science And Technology Co., Ltd.

May 30, 2016· PDF | This project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine powder. Ball mill is a cylindrical device that used to grind and blend raw ...

Ball mill / vertical / thin 14 30 t/h | Vertimill® series Direct Industry. VERTIMILL® for fine grinding is backed by over 100 years in expertise of mill design and .

Vertical roller mills (VRM) can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding. According to MIIT, grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball mill.

Grinding Classification Circuits robertd T09:51:3404:00. ... This means plant design is more compact / simple in comparison to ball mill / classifier circuit. On the other hand fineness is limited. ... so we have wet vertical ball mills and wet horizontal ball mills and dry vertical ball mills and dry horizontal ball mills.

There are three types of ball mills: horizontal, vertical and industrial. Horizontal Ball Mills. Horizontal ball mills are the most common type. The basic design is the same but the details can vary slightly. A drum, which is usually detachable, has a door that can be used to load in the material to be processed. Sometimes like for paint ...

The grinding process in ball mills and vertical roller mills differ fundamentally. In a ball ... grinding. Today, however, the OK mill has become an excellent example of a mill design that has overcome the difficult grinding conditions associated with finish grinding of cement clinker and related products.

Nov 18, 2008· My Tech. Report on Ball mill. ... ball mills: batch ball mill and continuous ball mill with different grinding media and different design depend on the nature of the input material and the nature of the output which I need. We discuss the types of ball mill, the basic principles of the ball mill, how it works, the details of design including ...

Jun 19, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball .

Stirred Mills have been proven to provide energy savings compared with traditional ball mills. The finer the product required, the more efficient stirred mills will be than a ball mill. The attrition grinding action, vertical arrangement, and the finer media size distribution contribute to make stirred mills more energy efficient grinding machines.

Throughout Ball Mill History, as an excellent ball mill suppliers and ball mill company, SBM ball mill . Ball Mill | Design Highlights MIKRONS Ball Mill form a .

Ball mills designed for long life and minimum maintenance overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30'' x 41'' . and as much as 30,000 HP. Larger ball mills are available with dual pinion or ring motor drives. Our mills incorporate many of the qualities which have made the Marcy name famous since 1913.

Vertical ball mill slakers are comparable to horizontal ball mills in cost, however, have much better turndown capability, and consume less energy. In addition, the temperature probe is located in the reaction zone for this type of mill, so a vertical ball mill can be optimized to maximize lime reactivity and reduce overall chemical consumption.

Download Ball Mill Design Software; Download Ball Mill Design Software. Our company has been devoted to mining machinery for 40 years. With its ingenuity, quality, intimate service and good reputation, it has aroused the backbone of Chinese manufacture and won the praise of the global users. We also choose us as a successful enterprise and a ...

Planetary Ball Mills are used wherever the highest degree of fineness is addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and ...

WhatsApp)

WhatsApp)