Grinding Wheel Dressing Calculator | Norton Abrasives

Grinding Wheel Dressing Calculator: Calculate the starting parameters when truing Norton products using diamond dressing rolls. Follow the steps below to .

WhatsApp)

WhatsApp)

Grinding Wheel Dressing Calculator: Calculate the starting parameters when truing Norton products using diamond dressing rolls. Follow the steps below to .

Dec 08, 2016· A downside of centerless grinding is you can''t have as many multiple axes operating on the workpieces. However, there are many parts where the process addresses the limitations of machining in terms of dimensions, materials, and surface finishes. That''s why we like to say that where machining ends, the centerless grinding process begins.

In the equation of Time for Cylindrical Grinding Cut Length of Cut = Length of job + OverTravel where, OverTravel equals to cm. And Feed/Rev. = w/2 (for rough cut) or w/4 (for finishing cut).

Dec 15, 2000· Achieving consistent and quality results from the centerless grinding process requires an understanding of the basic fundamentals. Most application problems associated with centerless grinding derive from a misunderstanding of the basics. This article explains why the centerless process works and how to use it most effectively in your shop.

Calculation of the machining time of cutting tools from captured images of machined parts using image texture features. ... This work aims to model the cutting process, correlate and optimise the ...

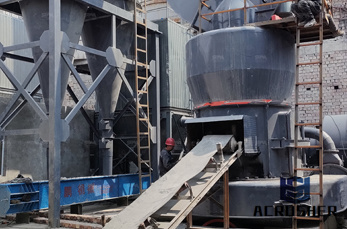

Grinding Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type. These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous. The grinding action is induced by relative motion between the particles of media the rods, balls or pebbles ...

The Grinding Process Grinding is a material removal and surface generation process used to shape and finish components made of metals and other materials. The precision and surface finish obtained through grinding can be up to ten times better than with either turning or milling. Grinding employs an abrasive product, usually a rotating wheel ...

What type of grinding are you doing batch in a lab, continuous production? Sizing of mills is a bit of an art form on the surface it is a volume issue but it is not just a simple volumetric calculation at the core of a good design, there are breakage functions involved, two .

Without basic time study measures, it is impossible to know whether work has improved or whether there are differences in performance in a unit. Studying Work as a Process. When practitioners conduct a time study, it is essential that they know what they want to study. Work is not strictly a set of disconnected tasks, it is a process.

Boring is the process to enlarge the hole which has drilled in an object. This formula counts required time for boring. Drilling is the process to drill a hole in an object. This formula counts required time for drilling. Facing is the process to remove the material from the surface at right angles to the axis of rotation of the job.

CustomPartNet is a free resource for engineers and manufacturers that facilitates product design and cost estimation. Learn about the process cycle and design for manufacturing (DFM) guidelines for a wide range of manufacturing processes, including injection molding, metal casting, machining (milling and turning), and rapid prototyping. Get fast and accurate cost estimates by using our ...

Calculation of Machine Hour Rate: For the purpose of computing the machine hour rate, each machine (or a group of similar machines) becomes a cost centre and all overheads are charged to a machine cost centre or to different machine cost centres if many such .

tion of profile grinding processes, an empirical process model was developed to allow application of the results from the analogy process to profile grinding. In the analogy process, a large number of trials with profile angles varying from ϕ = 2° to ϕ = 90°, and a stock varying from ∆s = .

The science of grain processing has now reached a point that, by knowing the characteristics of the feed (moisture, content, fiber, etc.) and using machinery with accurate measurements, the guesswork has been removed from pelleting. As a result, much more is required of the pellet mill operator in the way of knowledge and ability.

Computation Time On Grinding Process. Grinding process simulation based on rosinrammler, to develop a grinding process model, that is able to predict i the time evolution of the coarse fraction, which is considered as the total residue on the 200 m sieve, and ii the evolution of the fine fraction as a complete psd range between 200 and 1 m based on the rr.

~ramesh/ME338/

1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurry. The particles with attached air .

1 Over the past 15 years, minetomill studies have focused attention on the impact blast fragmentation has on concentrator throughput. Blasting provides the first opportunity for comminution – or size reduction. It is also a cheaper and more efficient process, compared to both crushing and grinding.

How to calculate cycle time for cylindrical grinding cycle time calculation of centerless grinding process By Chris Koepfer It''s a good bet that grinding is the Sometalworking process most associated with black Dec 06 2007 · How to calculate cycle time for cylindrical grinding machine

A problem for solving mass balances in mineral processing plants is the calculation of circulating load in closed circuits. A family of possible methods for the resolution of these calculations is ...

Dec 15, 2016· Process Variables and their Effect on Grinding Wheel Performance Grinding wheel recommendations, unless prepared for specific cases, are predicated on conditions which may be considered as average. Deviations from such basic conditions will generally affect the manner in which grinding wheels actually act.

The production time for a manufacturing process is primarily determined from the cycle time, but must also account for the defect rate, machine uptime, and machines used. Using these parameters, the run quantity, run time, down time, total production time, and production rate (parts/hr) will be calculated.

Cycle Time as Process Cash Flow Just as cash flow is a direct measure of company financial performance, cycle time is a direct measure of process and equipment performance. Cycle Time Throughput Yield The time to complete a task or collection of tasks. The desired process throughput is inverse takt time. The amount of processing cycle 9/04

computation time on grinding process. Help With Calculating Welding Costs and Times For example if the root process was going to be a 1000mm long 4mm thick Gas Tungsten Arc Welding GTAW deposit on a 20mm thick plate using a 60° included angle single Vee weld with a .

WhatsApp)

WhatsApp)