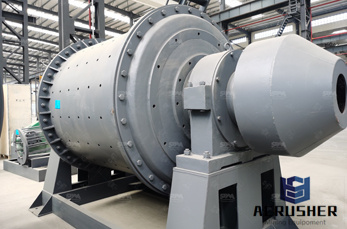

primary ball mill Mine Equipments

Ball Mills, Grinding Media, Primary, Secondary, Comminution, Size ... Description and images of ball grinding mills used in primary and secondary reduction of materials for the mining / .

WhatsApp)

WhatsApp)

Ball Mills, Grinding Media, Primary, Secondary, Comminution, Size ... Description and images of ball grinding mills used in primary and secondary reduction of materials for the mining / .

DESIGN, FABRICATION AND PERFORMANCE ANALYSIS OF A PLANETARY ROLL MILL FOR FINE GRINDING ... Laboratory Ball Mill shows that the machine is about 30% more efficient than the ball mill in terms of duration of ... especially for primary and secondary crushing, the same

Although rod mill installations are thus restricted in normal practice to the coarse crushing of soft and friable ores it is sometimes found that the most economical method of grinding an ore of not more than average hardness is to use a rod mill in the p,Primary and secondary grinding stage ball mill for ore.

The number of impacts in primary ball mills are far more frequent but have less magnitude than those experienced in SAG mills. The increased frequency is due to the Increase in charge volume (35 40% versus 5 10%), higher mill speeds, and the larger number of balls per unit charge weight.

POLYCOM HPGR ball mill grinding circuit > Grinding plants . Four POLYCOM systems are used for primary grinding. Four energysaving, lowwear ball mills are used for the wet process final grinding throughput 108,000. Intial Review of the Metallurgical Performance of the HIGmill in a energies to that of the ball mills in primary, secondary and ...

We can provide all elements of a mill drive system as a fully optimised solution to suit your process exactly, or individual mill drive gearboxes, girth gears, pinions and couplings as required. Designed to deliver exceptional levels of performance and value, David Brown Santasalo ball mill drives are optimised for primary and secondary ...

Ball mill used as the primary crisher for ore. Home product ball mill used as the primary crisher for ore. Autogenous and Semiautogenous mills . The AGSAG mills are utilized to grind runofmine rock or primary crusher processing, or an immediate size for further grinding in a ball mill, pebble mill, further expanded the use of large AGSAG.

If finer grinding is wanted two or three stage grinding is advisable as for instant primary rod mill with 75—100 mm (3″—4″) rods, secondary ball mill with 25—40 mm(1″—1½") balls and possibly tertiary ball mill with 20 mm (¾") balls or cylpebs.

Professional Primary And Secondary Ball Mill Primary Vs. Secondary, Primary Secondary Tertiary Colors, Primary and Secondary Sources Examples, Primary vs Secondary Immune Response, Primary Secondary Tertiary Sources, Difference Between Primary Secondary Sources, Primary and Secondary Growth, Primary or Secondary Source, Primary and Secondary Active Transport, Primary and Secondary .

Primary and secondary ball mill beltconveyers net. primary, secondary and tertiary crushing crusherasia. primary secondary and tertiary crushing beltconveyers . Primary,Secondary and tertiary crushing in aggregate The first stage in most aggregate production operations is the reduction and sizing by crushing. Get Price AMIT 135 Lesson 5 ...

Ball MillXinguang Mining Machinery is a professional mining solutions anreferencesd equipment manufacturer. We provide mining equipments such as cone ball mill tube ball mill dry magnetic separmagnetic separator large for primary and secondary ball mill

secondary ball mill circuit secondary ball mill design for mineral. mineral beneficiation grinding ball mill iccoss2017coza Ball Mill Ball mills are used for single stage fine grinding, regrinding process will pass through the primary mills and onto the secondary ball mill circuits, mill .

GRINDING CIRCUIT PRIMARY BALL MILLLING. Mill (grinding) Wikipedia, the free encyclopedia A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes. .. Rod mills are less common than ball mills for grinding mineralslike in a ball mill.

Ball Mill For Ore For Primary And Secondary Crushing. Gold ore crushing process and gold crusherold ore production process includes crushing, grinding, beneficiation three processesurrently,the gold ore processing methods are as follows first of all, send the large gold ore to jaw crusher evenly and continuously for primary crushing by vibrating feeder.

Rubber Mill Liners are chosen for most Primary, Secondary and Tertiary Ball Mills. In many cases rubber components are best suited for specific areas in AG and SAG mills. Learn more. PolyWIP™ Pulp Lifters. PolyWIP™ lifter inserts increase the life of premature worn steel pulp lifters.

screening ball mill primary_Metso Ball MillsA ball mill grinds ores and other materials to a typical product size of 35 mesh or finer. The feed to a ball mill is prepared by:Single or .

Ball mills are employed in either primary or secondary grinding applications. In primary applications, they receive their feed from crushers, and in secondary applications, they receive their feed from rod mills, autogenous mills, or semiautogenous mills. Regrind mills in mineral processing operations are usually ball mills, because the feed ...

Ball Mill For Primary And Secondary Grinding

· ROCKLANDS PRIMARY BALL MILL LIFTED INTO PLACE After 8 years of exploration, infill drilling, planning, design and development, construction of site The Primary Ball Mill is one of three mills in the mineral processing plant and is the heart of the operation, stream circuits that extract copper, cobalt, pyrite/sulphur, and magnetite

Apr 30, 2015· Grinding a Ball Nose End Mill with the Toycen Journeyman Tool Grinder Probably the most important thing about Ball or corner radius Grinding in your position, When your set up .

In primary ball milling, wear speed is largely independent of ball diameter and mill volume. (The same is true for secondary, tertiary, and regrind grinding.) In these applications, Equation 4 can be used to quantitatively predict how ball size and ball volume charges will affect wear rates.

Following primary/secondary crushing, the material is processed through a rod/ball mill grinding circuit ead of rougher/scavenger flotation that produces a copper concentrate.

Ball Mill For Ore For Primary And Secondary Crushing. A blend of primary and oxide ore, the circuit achieved in excess of 320 t h until the oxide was depleted the mw semiautogenous grinding sag mill and mw ball mill were assisted by a50 kw the target 80 per cent passing p80 size for the effective means for controlling the sag mill load, edna may.

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

WhatsApp)

WhatsApp)